An organized model that follows fundamental principles to achieve success and perfection in the deployment of Artificial Intelligence is known as an “AI factory.” To achieve the objectives, the AI factory includes fundamental elements, including people, data, platform, and procedure.

Similar to how a pharmaceutical factory makes drugs for patients, an AI factory makes solutions for its customers. Millions of services—from a straightforward android for your hand to a sophisticated weather report developer—are the end products of an AI factory. AI is used in many aspects of risk management and service provision.

In October 2023, Nvidia and Foxconn announced a joint project of constructing “AI factories,” a new breed of data centres that claim to have the supercomputing ability to hasten the creation of industrial robots, self-driving cars, and other autonomous devices. The project may very much emerge as a disruptive trend in the automobile industry.

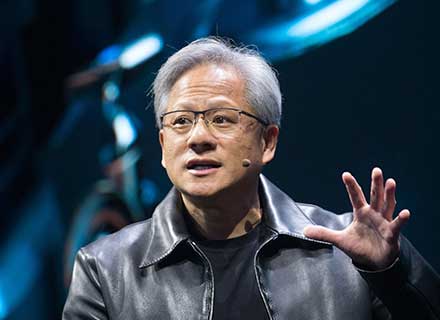

The partnership was announced at Hon Hai Tech Day in Taiwan by the founder and CEO of Nvidia, Jensen Huang, and the chairman and CEO of Foxconn, Young Liu. The AI factory, which will be constructed to filter, refine, and turn enormous amounts of data into useful AI models and information, is based on Nvidia GPU computer infrastructure.

“On the one hand, you’re constructing this cutting-edge EV car, and on the other hand, we’re building this full end-to-end system. With an AI brain inside that enables it to interact with drivers and passengers, as well as autonomously drive, supported by an AI factory that produces software for this automobile,” the joint venture informed the media, while adding, “This automobile will experience life and gather additional data. The data will be sent to the AI factory, which will update all of the AI fleet’s software and make software improvements.”

The collaboration between the AI factory and Foxconn expands upon their agreement to create platforms for autonomous vehicles, which was announced in January 2023. By that deal, Foxconn agreed to serve as the major provider of electronic control units (ECUs) for the automotive industry. These ECUs will be constructed using Nvidia’s Drive Orin system-on-a-chip (SoC), a supercomputing AI platform that supports autonomous driving capabilities. Foxconn has also declared its intention to produce ECUs using Nvidia’s next-generation SoC, Drive Thor, starting in 2025.

As part of that collaboration, Foxconn announced that the vehicles it produces as a contract manufacturer will be built with Nvidia’s Drive Hyperion 9 platform. This platform includes Drive Thor as well as a collection of sensors like cameras, radar, lidar, and ultrasonic that are essential for self-driving capabilities.

Understanding The Concept

An AI factory is basically a well-organized model, which works on the basic principles of delivering success and excellence in AI deployment in an industrial environment. An AI factory combines elements like people, data, platforms, and processes to deliver the goals.

An AI factory’s goal is to create solutions for its clients.

“From a simple android of your hand to a complex weather report developer, a million services are the products of an AI factory. AI is in all from providing support services to risk management,” stated AnalyticSteps, while explaining the phenomenon.

While the Foxconn-Nvidia joint venture holds a promise of positively disrupting the automobile industry, the initiative also has to go through challenges like constantly understanding the goals of an AI factory, staying future-proof by researching, understanding and executing advanced AI technologies before the rivals and strengthening the data security front.

The AI factory approach is a method of investigating AI algorithms and logic, in which a problem is first identified by experiments and observations.

“The problems identified are then solved. Hypotheses and statistics are then developed according to the situation. The developed hypotheses often served as fundamental principles. And are important for mechanism and functioning,” AnalyticSteps explained the concept further.

A successful AI factory board needs to have a high-level and dedicated team of data leaders, as data is the basic raw material for an AI industry. Data leaders help in providing direction and control to an AI factory, apart from reviewing and validating the progress of the data collection. These specialists work collectively to achieve a single role, which is ensuring the real-time information flow and transparency of a project.

The AI factory also needs a team of experts, which will cover domains like business, data, software, and digital technology. Together, these professionals will work as a hybrid structure. While one of them gathers raw data, others search for suitable technology to implement it within the AI model, in order to execute the project within a short time span.

The AI factory works with a combination of proprietary, cloud, and open-source solutions. Even, existing AI technologies are used to develop the latest and advanced AI services. The data collected by human professionals get fed into an AI process to develop an automated service.

To make an AI factory successful, the Foxconn-Nvidia joint venture needs to reconstruct the structure and reimplement the AI algorithms, apart from seamlessly combining the five factors named data, product, process, platform, and people.

“Data is the raw material, products are AI services or final AI technologies, process is the blend of AI methodologies and intermediate technologies, platform dedicates the team of experts, and people here are the persons such as data engineers, digital marketers, or anyone who is utilizing or producing AI services,” stated AnalyticSteps

AI is making a profound impact on the manufacturing industry, offering a myriad of benefits. It significantly enhances product quality, reduces time to delivery, and boosts efficiency and overall performance.

Conclusion

AI’s role in manufacturing extends to increased efficiency and productivity, allowing predictive maintenance to prevent equipment breakdowns and repairs. This technology is not only revolutionizing the manufacturing sector but has the potential to transform it completely, driving productivity and streamlining processes, as well as offering upsides such as customization and personalization.

Job transformation is also on the horizon, as AI may replace manual roles but simultaneously create opportunities in AI system design, maintenance, and data analysis, necessitating workforce adaptation.

In summary, AI is shaping a manufacturing landscape characterized by heightened quality, efficiency, and productivity. This change may be disruptive to the current economic model but new opportunities are expected to develop.

Through its AI factory, the Foxconn-Nvidia joint venture, apart from developing and deploying AI on a common platform for its internal teams, will be able to reduce its product manufacturing time by standardizing operations across the departments. Also, the JV will have its secure common data architecture, apart from expanding its operations quickly to other industrial units.

A correctly deployed AI model brings an ocean of possibilities for any venture. A successful ‘AI Factory’ ensures that the tools, processes, and teams within a company remain transferable and replicable, thereby giving the business overall agility.